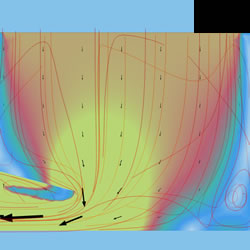

At the customer's request, the formation and spreading of an explosive atmosphere and the optimal necessary explosion protection measures can be determined and analyzed using the most advanced software tools. In this case, mathematical equations describing physical processes are solved, and a 3D model (stationary or time dependent) or simulation is made, which can be used for analysis/determination of:

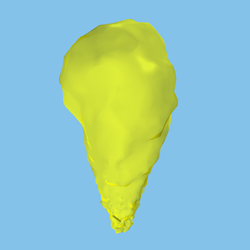

- the size of explosion hazardous areas (zones),

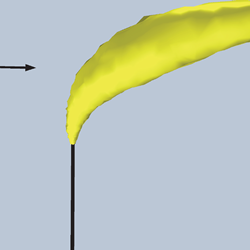

- the propagation of an explosive atmosphere in space and time,

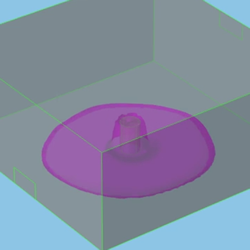

- appropriate local extraction and general room ventilation,

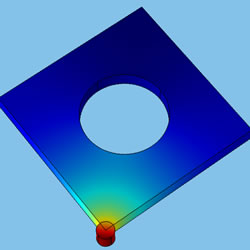

- hot parts of the equipment which are not easily accessible with temperature sensors,

- optimal micro-location of LEL detectors in the plant

- inertization of the processing equipment,

- the air flow profile inside a dryer (pockets of stationary or swirling air),

- etc.

Because large computational power is usually required for 3D modeling and simulation, numerical calculations are performed on a supercomputer abroad.

Some examples from practice (click for larger view):